Fifty First Parallel: what Lethbridge can expect from its first cannabis production facility

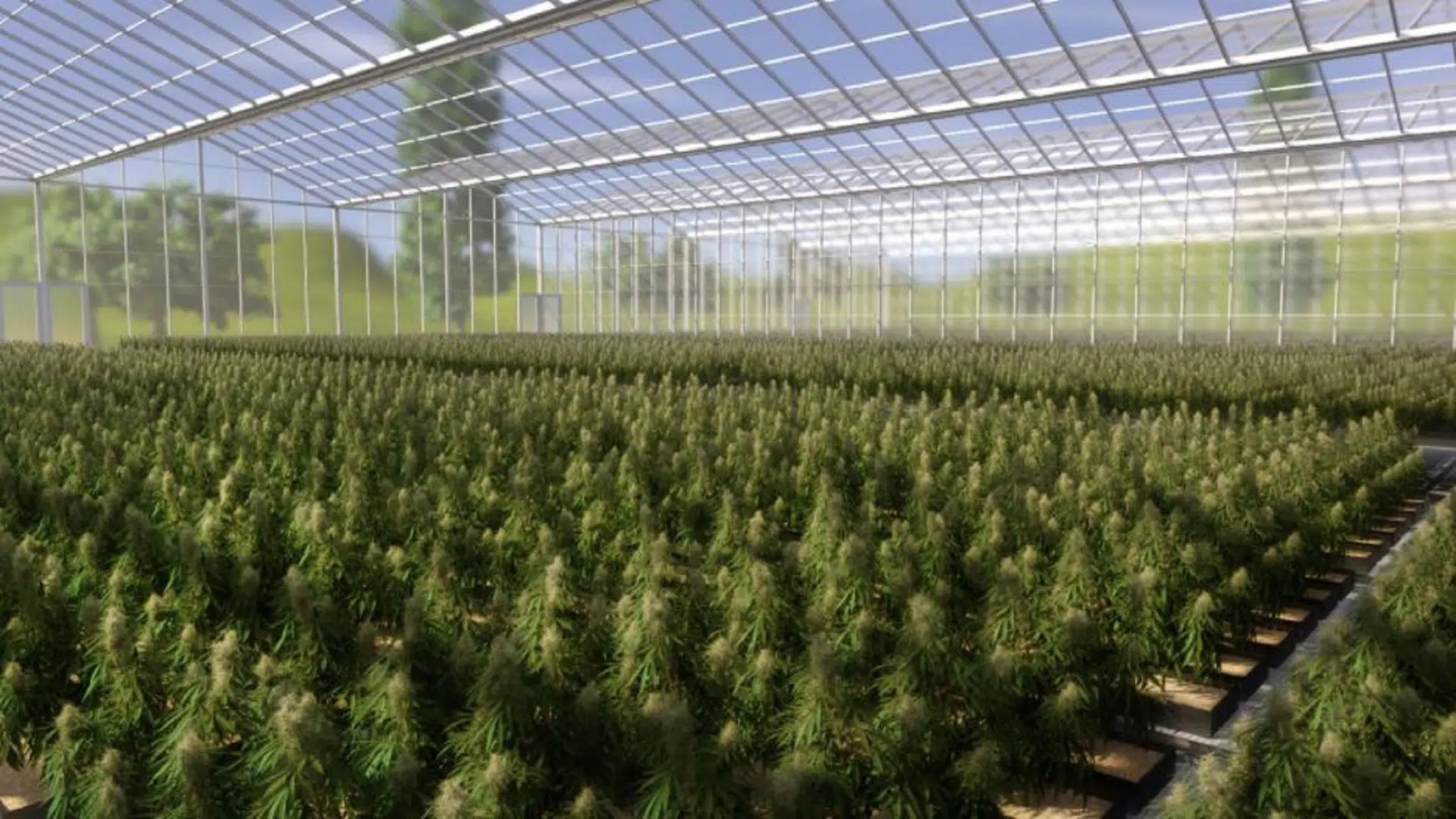

LETHBRIDGE – When most people think of a marijuana growing operation, the picture that most often comes to mind is a dark basement or warehouse, tubing and ventilation hoses, dozens of electrical-grid draining lights, and wires everywhere.

That couldn’t be further from what Fifty First Parallel Company President Jason Kujath says he and his team are planning for Lethbridge’s Sherring Industrial Park.

In fact, not only will the massive greenhouse facility use far less electricity and water than a traditional grow-op, but the company is also working on signing research contracts with the University of Lethbridge and Lethbridge College, and will embark upon a number of local employment initiatives.

Company History